25 Sep Controlling dietary buffering capacity in piglet feeds

Giannis Karvelis, Nuevo S.A, g.karvelis@nuevo-group.com

Published on December 10,2014 – www.WATTAgNet.com

In every intensive pig production system, the challenge of a smooth transition from lactation to weaning is crucial for optimal productive efficiency. The story is definitely not new and has been thoroughly studied, analyzed and documented by several researchers and field practitioners. To summarize, it suffices to say that the main challenges for a piglet in the transition phase are the new environment, the mixing with other piglets, the new type of feed and, last but not least, the still immature immune and gastrointestinal systems.

For all of us involved in piglet feed formulations what we need to understand is that before we even consider targeting growth rates, we must first help create and cater for a mature intestinal system. This will help towards a higher feed intake, a stable microbial population, a better nutrient digestion and therefore improved growth and feed conversion efficiency.

With this in mind, feed formulations for young pigs should not only be related to the amino acid profile or the energy content of the diet, which of course are important (and expensive) parameters, but also to other nutrients and key parameters. Such is the case for dietary acid binding capacity (dABC), which is closely related to selected raw materials included in the final feed and has a tremendous impact of feed digestibility and gut development.

Acid binding (or buffering) capacity

The term acid binding (or buffering) capacity is used to describe the resistance of a diet to the pH reduction by gastric HCl. Hydrochloride secretion is a normal gastric function required to initiate protein digestion. In feed formulation terms, dABC is expressed in milliequivalents (meq) of hydrogen(+) fixed at pH=3 . The following equation can be used for its calculation:

- Dietary Acid Binding Capacity = {(50-ml NaOH)*N / P} x 1,000

N= Normality of NaOH (eq/l)

P= Weight of the sample

High buffering capacity leads to lower digestibility of organic matter and crude protein and therefore adversely affects the performance of piglets. At the same time, high values of dietary buffering capacity have a significant effect on intestinal fermentation occurring in the ileum and caecum where fermentable energy is the limiting factor to bacterial growth. This will result in increased proteolysis and in turn increased amine and ammonia releases, which are toxic substances leading to diarrhea and poor growth.

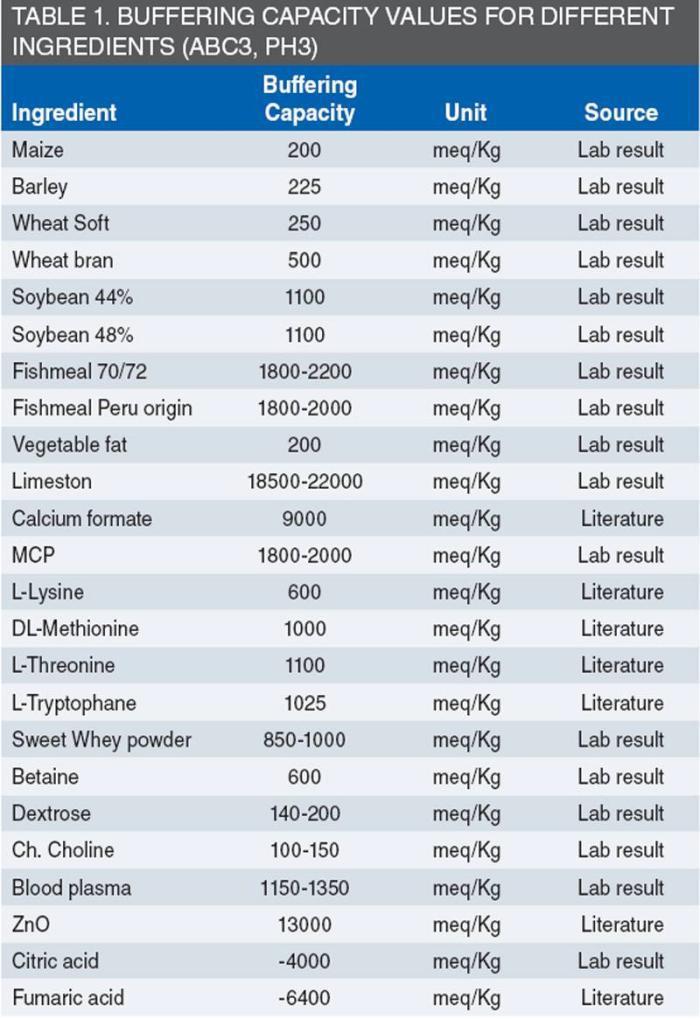

Moving to the more practical part of feed formulation, the final feed buffering capacity value is heavily depended on the sources of minerals and proteins since the cereals and cereals by-products are characterized by the lowest values (see Table 1).

Faced with this, the first action that needs to be carried out is to reduce, in the formulated piglet diet, the Ca and P levels (for the first two weeks after weaning) down to 0.60-0.65 percent and 0.35-0.40 percent, respectively. This needs to be done through the (partial or total) replacement of limestone (calcium carbonate) with calcium formate (as a Ca source) and the parallel use of monocalcium phosphate instead of dicalcium phosphate (as a P source). This will inevitably lead to increased cost but it will effectively reduce the feed buffering capacity since the absolute value for limestone is 18.000-20.000 meq/Kg compared to calcium formate, which is a much lower 8.500-9.000 meq/Kg.

Secondly, it is also important to keep the crude protein level of the feed as low as possible while maintaining a good and balanced amino acid supply. Selective and careful, as well as contained, use of high protein raw materials, with the parallel use of synthetic amino acids can easily achieve this goal. As a rule of thumb, aim for a 17-18 percent crude protein but maintain lysine at a minimum 11.5-12.0 gr SID Lys/Kg, with the rest of the key essential amino acids balanced on this. However, take care and do not blindly reject good high value raw materials simply based on their high protein content and apparently high buffering capacity. Look carefully at the total blend of raw materials available, their inclusion in the feed depending on cost as well as the targeted feed buffering value, and make the final judgment based on science and field experience.

To summarize — without making any reference to the option of adding organic acids in the feed to artificially lower the buffering capacity value — it is important to stress that it must be left to the experience of the individual pig nutritionist which raw materials are eventually included in a specific feed and at what maximum inclusion levels while he or she considers all other farm parameters and targets such as weaning weights, health status, management, machinery, building facilities and so on.

The optimum goal should be a feed with an acid binding capacity of less than 650 meq/Kg.

Feed ingredients vary widely in the buffering capacity.

Find more about NUEVO’s macro-premixes for suckling and weaning pigs